Sydney-based biotechnology company, Smart MCs, has been awarded an AUD$600K Australian Government Accelerated Commercialization grant to revolutionize the bioprocessing industry with edible microcarriers (MCs) for the emerging cultured meat sector. The company will set up a fully automated edible microcarrier production line with grant funds.

Founded in 2022, Smart MCs focuses on developing efficient and cost-effective methods for large-scale expansion of cells with a special emphasis on cellular agriculture.

The startup was part of the sixth cohort of Big Idea Ventures, which launched last October along with 16 other companies. Additionally, it successfully locked in two minimum viable products, closed a pre-seed round and expanded its team and advisors.

“We are thrilled to receive this grant from the Australian Government, which will allow us to take microcarrier production to the next level and support the emerging cultured meat industry,” said Peir Radfar, CEO of Smart MC.

Edible microcarriers

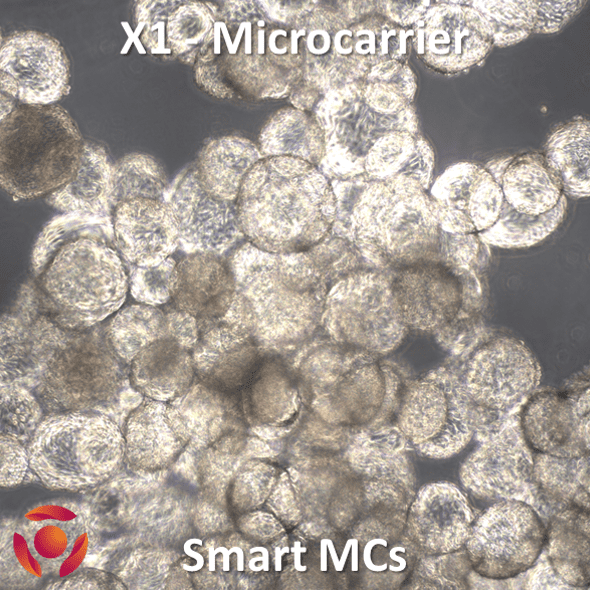

One of the main challenges in meat farming is scalability. Cells must attach to microcarriers (a surface) to grow and proliferate in bioreactors, Smart MC explains. Microcarriers are important in bioprocessing for efficient cell growth, allowing rapid cell proliferation. If the microcarriers are edible, this is a promising technology for improving cultured meat.

The recent development of edible microcarriers by smart MCs made from off-the-shelf food ingredients alleviates concerns about the non-edibility of the carriers, which have historically been used in the pharmaceutical industry.

Rapidly growing demand

With the establishment of a fully automated microcarrier production line, Biotech will significantly increase its production capacity, allowing it to respond to growing demand as cultured meat companies look to expand their product lines. This will bring significant changes to the bioprocessing industry and enable scalable production of cultured meat, ultimately accelerating the development of this innovative food technology.

“Our investment in this new facility will not only enable us to meet the rapidly growing demand for our products, it will also allow us to play a key role in the development of this innovative food technology,” added Radfar.